BuckeyeDennis wrote:RFGuy, how did you measure the airflow? I’d like to be able to do that myself. As for the sound pressure, are you using a smartphone app or a dedicated instrument?

I do have some quiet dust-collector info that might be of interest. A while back, I bought a new-in-box Jet 2HP dust collector with a canister filter. It was normally a $750 unit, IIRC, but it had some cosmetic shipping damage to the canister, and it had a 3-phase motor. Asking price was $200, so I snapped it up and then spent $200 for a VFD to power it.

While my primary purpose for the VFD was simply to power the motor, the variable-speed capability turned out to be pretty amazing. Subjectively, the noise level drops by about 80% when I reduce the blower speed by 20%. At 50% speed, it’s whisper-quiet. And as this unit is rated at 1200 CFM, it’s still moving a LOT of air.

So, I have the Extech AN100 Thermal Anemometer (pic below). I paid $140 on Amazon for it, so it wasn't cheap. There were a few alternatives on Amazon for about half that price, but I couldn't find one with decent reviews. At the time, I was debugging some balance issues room-to-room with my HVAC system. It was cheaper for me to spend that much and re-balance it myself than to call an HVAC guy out. Since then, I have used it a few times to do dust collector experiments. It helped me to decide to switch to my ShopVac setup with cyclone over my DC3300. A lot of the shop testing I have been doing, I am more interested in reference measurements (A-B) than absolute measurements. So, I don't know how accurate my unit really is. Also, I believe the preferred method for testing DC airflow is to have a certain length of straight pipe hooked up to the dust collector and insert an Anemometer probe into this duct at a certain length, which I can't do with my unit.

For sound level, I have used both smartphone apps and SPL meters. Yesterday for this data, I used my Radio Shack SPL meter because all measurements were above the minimum 60dB range on it. I think an app on a decent smartphone would work just as well.

That's interesting on the 3 phase dust collector (DC) and congrats on having one of those. I know 3 phase motors are supposed to be less noisy than 1 phase motors, but I would suspect that airflow noise (impeller and airflow at end of hose/tool) would dominate. For example, look at my data here for hose versus no hose on the Festool. If I remove the hose and turn the unit all the way down, then I can get near the factory spec'ed 62dBA noise level. However, I don't find DC/vacuums to be very useful with hoses/ducts removed.

Look at how much the noise level went up with hoses on my vacuum.

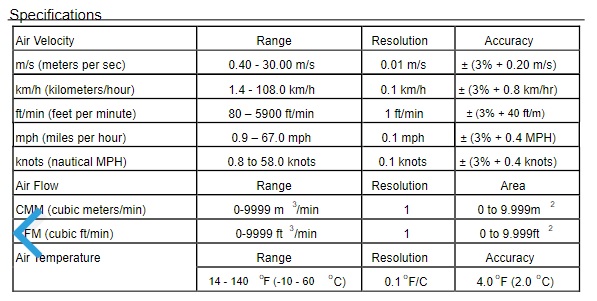

That's a really nice setup and if you do get an Anemometer, you could measure the airflow at the tool while you vary your Jet DC. Point being you could dial back the DC to cut down on noise, if you have sufficient airflow at that particular tool to meet its needs. The Anemometer that I have has several unit settings. The main one is in ft/min, but it will do CFM if you set the area in the meter. To save time yesterday, I took all measurements in ft/min and calculated the CFM numbers based on the area of that measurement. BE CAREFUL though if you decide to purchase one of these. You have a very powerful DC and it could easily be above the range of operation for the fan on an Anemometer. The cheaper units can easily have the fan burn up when placed into a fast air stream like your DC ducts at over 1000CFM, which is why I think they use probe style Anemometers. My unit is a bit more robust, but also would probably have trouble in greater than 1000CFM airstream. Specs for mine are below and it claims it could handle it, but I haven't tried it yet. Of course, you could start with your DC at its minimum setting and slowly raise the speed to see if the Anemometer ever goes out of range...to protect it.

UPDATE: Just ran a quick calc and with your 1200CFM DC, if you have 6" duct that works out to 6000 ft/min which according to the specs below is right at the end of the range on my Anemometer. Assuming the entire range is useable and linear, you could probably use the model Anemometer that I have. Once a little bit of static pressure loss is introduced with some ducting, you should be within range on the unit for measurements. If running smaller than 6" duct, it would definitely out of range this model due to the the higher ft/min of the airstream.

- AN100.jpg (70.04 KiB) Viewed 11332 times

- AN100specs.jpg (79.08 KiB) Viewed 11325 times