Page 2 of 2

Re: Mounting a Digital Readout

Posted: Sun Jan 04, 2015 7:12 pm

by beeg

jsburger wrote:OK, I have not posted here in a long time. Why does the picture I included not show up?

Tomorrow the ADMIN will fix that problem by WHOPPING the puter on top and spitting in the back of it.

Re: Mounting a Digital Readout

Posted: Sun Jan 04, 2015 8:20 pm

by jsburger

beeg wrote:jsburger wrote:OK, I have not posted here in a long time. Why does the picture I included not show up?

Tomorrow the ADMIN will fix that problem by WHOPPING the puter on top and spitting in the back of it.

Great!!! I have done that before so I know it works.

Re: Mounting a Digital Readout

Posted: Fri Jan 18, 2019 9:10 am

by RFGuy

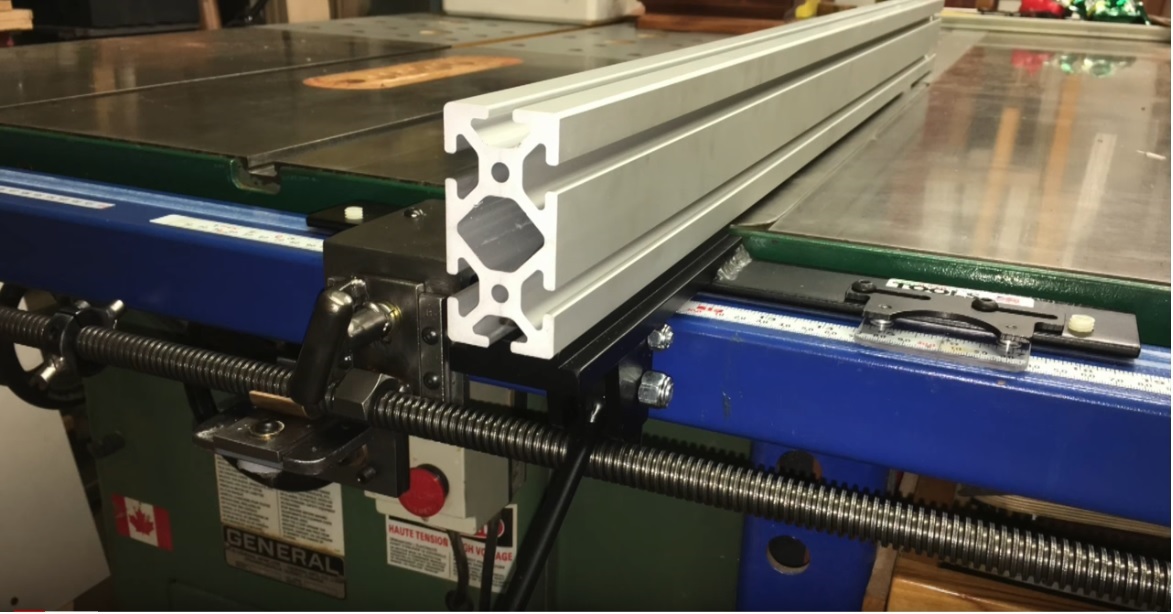

Owad wrote:I got tired of adjusting the height of the auxiliary table, and tried attaching the DRO to a floating table instead. The DRO is very light, and the table doesn't sag at all. With the configuration pictured below, it's possible to do cuts up to about 16.5" inches. With no gap between the tables, the maximum is 12.75".

It has been a few years since this was posted...just curious as to how well this is holding up? Sorry, I only recently discovered the forum and saw your post. Any issues with the Wixey DRO on the Shopsmith?

In addition to attaching a DRO, I would be interested in knowing if anyone ever thought of, or attempted to attach a threaded rod to the Shopsmith tables (see link below). Idea would be a poor man's version of an Incra system. Of course, the Achilles heel with this or getting a full blown Incra setup is the breakdown for other Shopsmith functions, but if one had a dedicated Shopsmith for TS it could be attractive for the precision offered in indexing and measurement.

One thought for this for large width cuts would be to place the fence on a floating table. Instead of waytubes, threaded rod could be used inside of the waytube holder with threaded plugs placed inside the ends of the waytube holders. Just a thought, but this wouldn't work for shorter rip cuts.

https://www.youtube.com/watch?v=zMLhV05iWT4&t=45s

- thread.jpg (170.14 KiB) Viewed 10321 times

Re: Mounting a Digital Readout

Posted: Sat Jul 01, 2023 10:28 pm

by Owad

RFGuy wrote: ↑Fri Jan 18, 2019 9:10 am

It has been a few years since this was posted...just curious as to how well this is holding up? Sorry, I only recently discovered the forum and saw your post. Any issues with the Wixey DRO on the Shopsmith?

This is my first time on the forums in a few years, and I just saw your post. I don't use it anymore. It was a hassle swapping it on and off, and I always felt like I had to be gentle with it. I also found that while my work often needs precision, it rarely needs that sort of accuracy.

Re: Mounting a Digital Readout

Posted: Sun Jul 02, 2023 10:14 am

by RFGuy

Owad wrote: ↑Sat Jul 01, 2023 10:28 pm

This is my first time on the forums in a few years, and I just saw your post. I don't use it anymore. It was a hassle swapping it on and off, and I always felt like I had to be gentle with it. I also found that while my work often needs precision, it rarely needs that sort of accuracy.

Thanks. I appreciate the feedback. I still haven't gotten around to trying this out on my Mark V yet...only because I haven't found the right DRO that I want to try to shoehorn onto the Mark V 520 table system yet. I also primarily want it for precision. Though I may desire higher accuracy, I know for most, if not all, woodworking applications that I do it is overkill. Thanks again.

Re: Mounting a Digital Readout

Posted: Mon Jul 10, 2023 1:09 pm

by BigSky

I may try one of these but if I do my first attempt will be to mount it UNDER the tables

Re: Mounting a Digital Readout

Posted: Mon Jul 10, 2023 2:39 pm

by RFGuy

BigSky wrote: ↑Mon Jul 10, 2023 1:09 pm

I may try one of these but if I do my first

attempt will be to mount it UNDER the tables

Yeah, this is my goal as well. I keep casually looking for different DRO options...trying to find an appropriate linear measurement rail that can be either mounted directly under the tables or from the 520 rail extrusion bottoms, but then the challenge becomes access to the reader/LCD position and mounting to reference the 520 fence, etc. I have seen a couple of new Chinese DRO's on Banggood's website that are cheap enough to spend on and if they don't work, not much is lost.