Page 9 of 12

Re: Mark VII “Project Machine”

Posted: Tue Oct 10, 2023 1:47 pm

by shipwright

No, it’s because the best deal on Amazon was for a five pack of the bearing that fits the single bearing quill. I have a Mark 5, a mark V 510, and the Mark VII. I figured I’d do them all just for fun. That leaves me with two lonely bearings so I thought if it fits, I would replace both in the 510. AFIK the second bearing doesn’t do much and seldom wears so if these don’t fit I’ll just leave that one.

Re: Mark VII “Project Machine”

Posted: Tue Oct 10, 2023 11:23 pm

by JPG

So you have a two bearing quill on the 510? I do not know if the two bearing(there are multiple variations) quill uses the same bearing as the M5/MVII.

i.e. you may have 3 orphans.

Re: Mark VII “Project Machine”

Posted: Tue Oct 10, 2023 11:27 pm

by shipwright

We will find out tomorrow or the next day. I think I read that the main one is the same but the second one may not be.

I’ll keep you posted.

Re: Mark VII “Project Machine”

Posted: Wed Oct 11, 2023 7:05 pm

by shipwright

JPG wrote: ↑Sat Oct 07, 2023 8:33 pm

I consider the pinned follower to serve the same purpose as the wire loop on the m5. IMHO the pins only become relevant with sluggish response of the floating sheave due to either too fast adjustment of the speed dial or inadequate lubrication of the floating sheave. Main purpose is non-rotation of the inner race of the control sheave bearing.

While I’m waiting for my new eBay sheave and my new printed cam to arrive I’ve been giving this some thought.

For the first part, sluggish return to high speed would be a good indicator that it’s past time for lubrication. That makes it actually more of a good thing than a bad one.

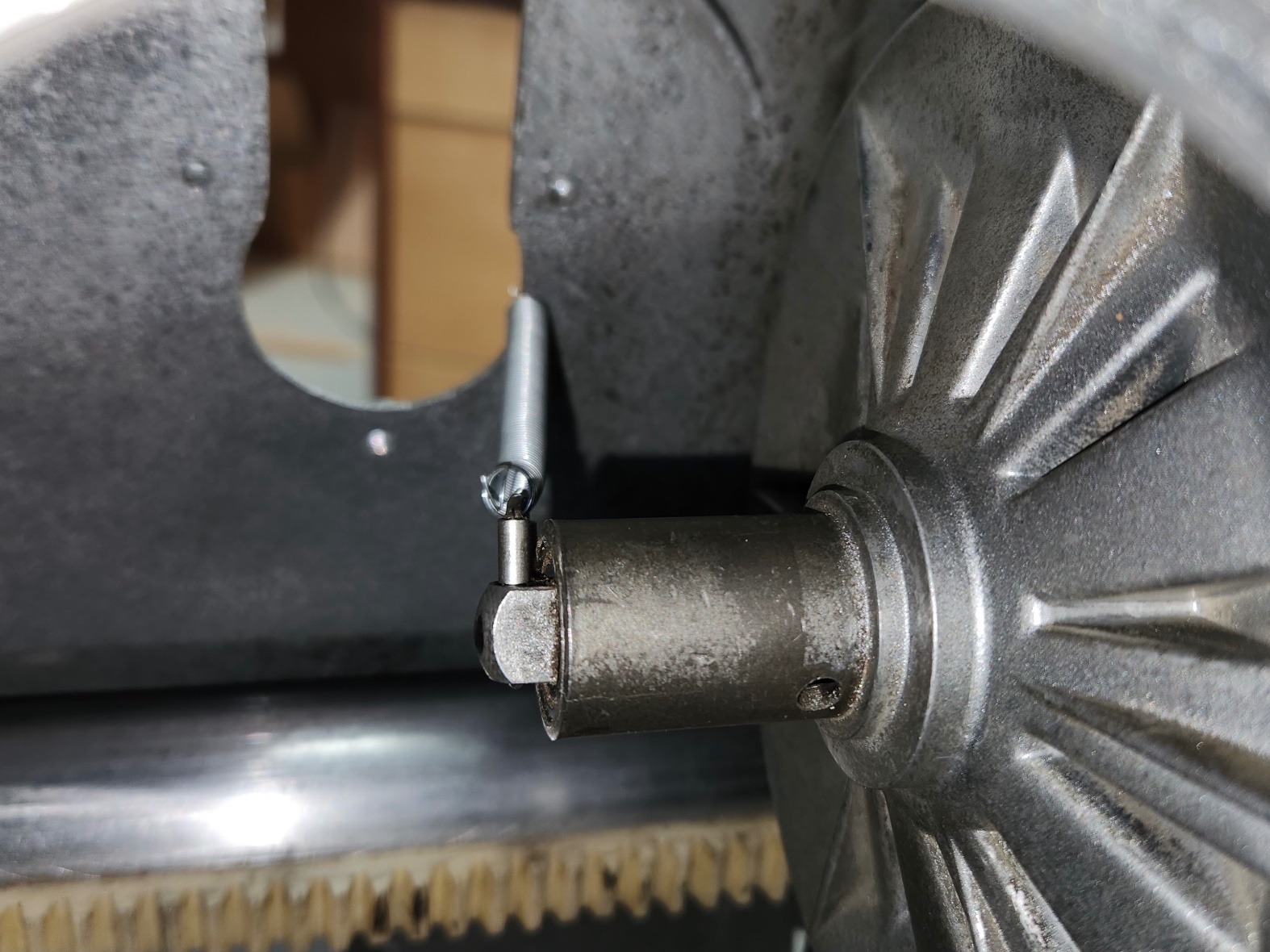

The second part made more sense to me. You do want to prevent the inner race from rotating so I thought I’d try a spring between the button bearing’s bail and the headstock case. The one I have in the pics is very light and may need some tweaking but I think the concept works. The idea is enough tension to prevent spinning but not enough to create an axial pulling force on the bearing. I think it can be quite light as I don’t think it would take much to prevent spinning if the bearing is good.

- 20231011_125713_Original.jpeg (503.39 KiB) Viewed 2533 times

- 20231011_125648_Original.jpeg (471.97 KiB) Viewed 2533 times

Re: Mark VII “Project Machine”

Posted: Wed Oct 11, 2023 8:49 pm

by JPG

Sluggish movement towards slow creates wear pressure on the quadrant(MV) or cam(MVII). The increased speed dial indication remains a mystery???

Re: Mark VII “Project Machine”

Posted: Wed Oct 11, 2023 9:21 pm

by shipwright

But sluggish movement toward slow would be no different from MkVII follower to button bearing.

In either case, time to lubricate.

Re: Mark VII “Project Machine”

Posted: Wed Oct 11, 2023 10:09 pm

by JPG

The problem with sluggish response to adjusting towards slow is the control sheave is squeezing the belt. That squeeze is relieved only by the floating sheave response(opening and creating less tension).

Re: Mark VII “Project Machine”

Posted: Wed Oct 11, 2023 10:12 pm

by shipwright

I get that but it’s the same for either the follower or the button, is it not?

Re: Mark VII “Project Machine”

Posted: Wed Oct 11, 2023 10:15 pm

by JPG

Yep. Control sheave butting against whatever is trying to move it.

Re: Mark VII “Project Machine”

Posted: Sat Oct 14, 2023 6:21 pm

by shipwright

Good news / bad news. I got the 3D printed cam and immediately broke it while fitting the shaft.

- 20231012_151045_Original.jpeg (430.3 KiB) Viewed 2468 times

So on to another angle of attack. I decided that the cam could be solid and much more robust if I was going to use a button bearing and have no need for a flanged edge. When you discard the U shaped follower and its roll pins the cam design becomes much simpler to reproduce. I decided to try some Purpleheart I had around and it only took maybe an hour all together to make what I think will work well. Time will tell. I’m still waiting for the eBay sheaves to arrive.

The finished cam is pictured here and a detailed step by step to make one is here.

https://photos.app.goo.gl/mV1QkEDC9PVcD54C6

- 20231014_142557_Original.jpeg (464.62 KiB) Viewed 2468 times