Building a back porch - advice needed

Moderators: HopefulSSer, admin

Hi,

This may or may not be of interest but I've been looking at sheds the last month or so. Some are metal, plastic, composites, conventional stud and plywood/flake board and even interlocking timbers. You can get many many sizes shapes styles and prices from hundreds to some that are about half what we purchased our house for.

Where we live you need a permit for anything much larger then a bread basket and there are a set of rules about how many, how big, where they are placed and about anchor them. Most of the rules have to do with safety issues like have lots of loose parts flying in a major storm or have the roof crash in during heavy snows and are there for you... and a few have to do with keeping the city from looking like a junk yard. I get the impression that some think they are there simply to make life hard for them.... I don't think that is true in most cases.

So anyway as I was reading the post I got to thinking that perhaps a shed might be another choice. Since I've also been doing some playing with sketch up (and getting other peoples models to play with) I found two that I could stick together to illustrate my thoughts.

[ATTACH]9666[/ATTACH]

I of course have no idea what your property might look like or the home layout but this shows a home with an open front porch, covered stairs to a shed and I added a car port to keep the car dry and cooler... perhaps a bit more roof could make the house to car a little dryer trip as well.

I should also point out that it might just be cheaper to have the shed kit delivered to you and do the assembly rather then purchasing the parts to do it yourself.... at least that seems to be what I'm finding.

Ed

This may or may not be of interest but I've been looking at sheds the last month or so. Some are metal, plastic, composites, conventional stud and plywood/flake board and even interlocking timbers. You can get many many sizes shapes styles and prices from hundreds to some that are about half what we purchased our house for.

Where we live you need a permit for anything much larger then a bread basket and there are a set of rules about how many, how big, where they are placed and about anchor them. Most of the rules have to do with safety issues like have lots of loose parts flying in a major storm or have the roof crash in during heavy snows and are there for you... and a few have to do with keeping the city from looking like a junk yard. I get the impression that some think they are there simply to make life hard for them.... I don't think that is true in most cases.

So anyway as I was reading the post I got to thinking that perhaps a shed might be another choice. Since I've also been doing some playing with sketch up (and getting other peoples models to play with) I found two that I could stick together to illustrate my thoughts.

[ATTACH]9666[/ATTACH]

I of course have no idea what your property might look like or the home layout but this shows a home with an open front porch, covered stairs to a shed and I added a car port to keep the car dry and cooler... perhaps a bit more roof could make the house to car a little dryer trip as well.

I should also point out that it might just be cheaper to have the shed kit delivered to you and do the assembly rather then purchasing the parts to do it yourself.... at least that seems to be what I'm finding.

Ed

- Attachments

-

- ScreenHunter_03 Jul. 21 00.06sc.jpg (35.92 KiB) Viewed 1925 times

{Knight of the Shopsmith} [Hero's don't wear capes, they wear dog tags]

I've looked at those buildings with a workshop in mind and I've been amazed at how expensive they are. Then I priced building one myself and decided they weren't that expensive after all!

My wife is pretty set on having a screened in back porch. Some place we can grill and hang out and be "outside" but not be eaten up with these giant mosquitoes that Texas keeps sending over to invade us. There's an existing vehicle covering right off from the porch that we built when we originally lived there. I hope to be able to build a walkway covering between the two. It's a pretty short span, so that shouldn't be a problem. The porch will be off the back left corner of the house.

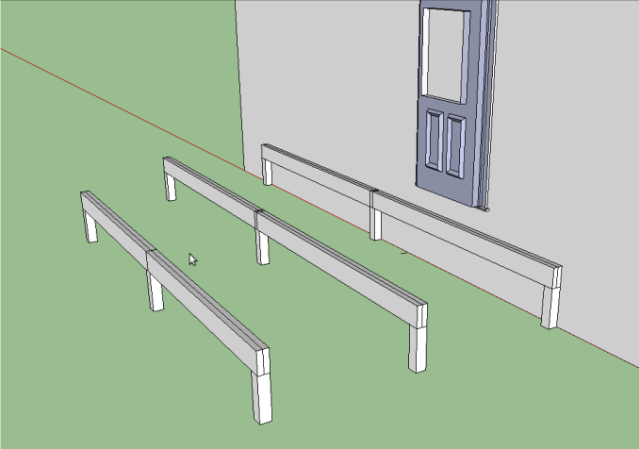

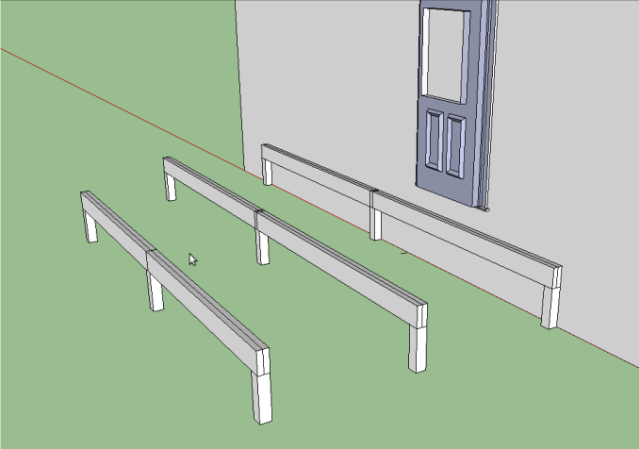

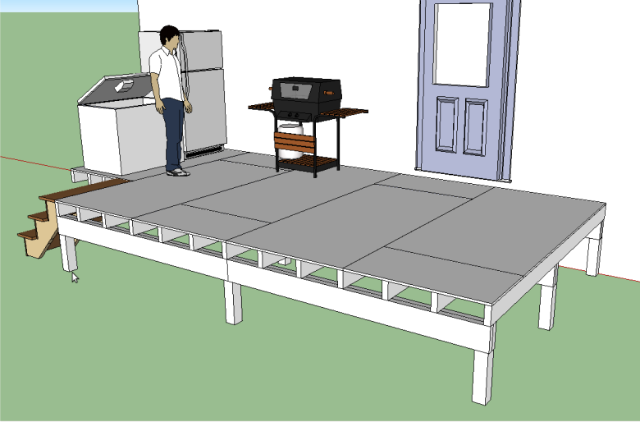

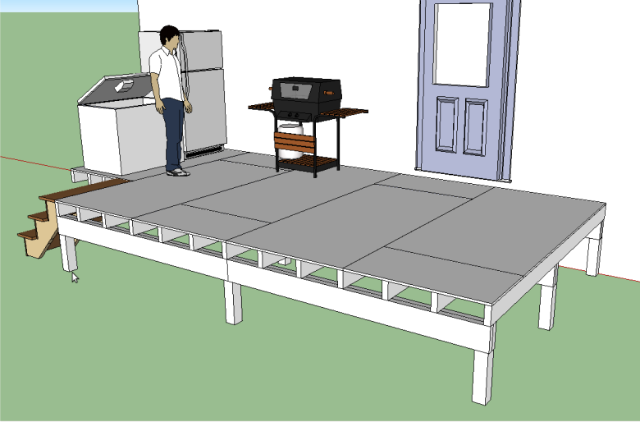

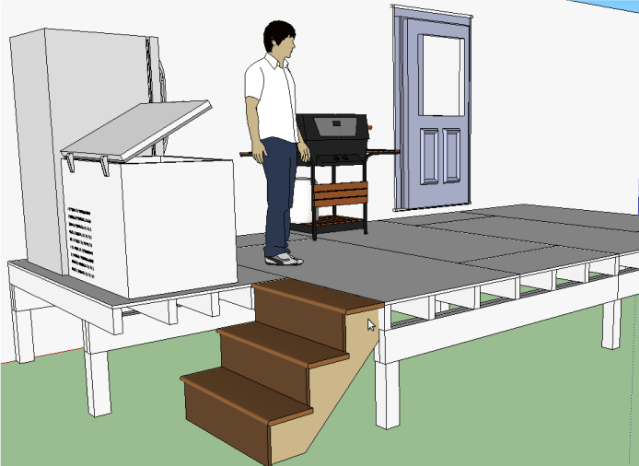

Here's what I've come up with in Sketchup. I'm trying to keep it simple and cost efficient, but functional.

Starting out with the 4x4 posts and support beams. The beams are 2"x8" and doubled. Is this necessary for the center span? Should I put a support brace tying the beam together for stability? I took a guess at the height of the posts, but that should be pretty close.

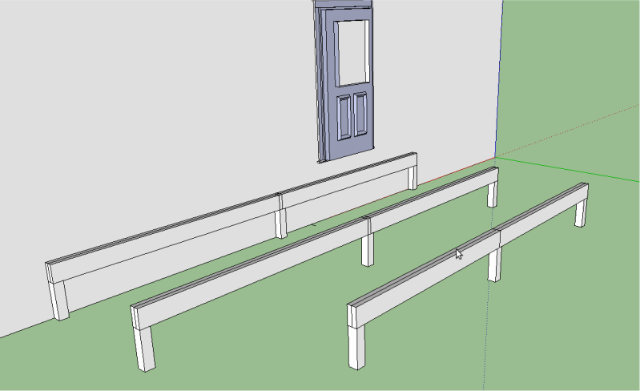

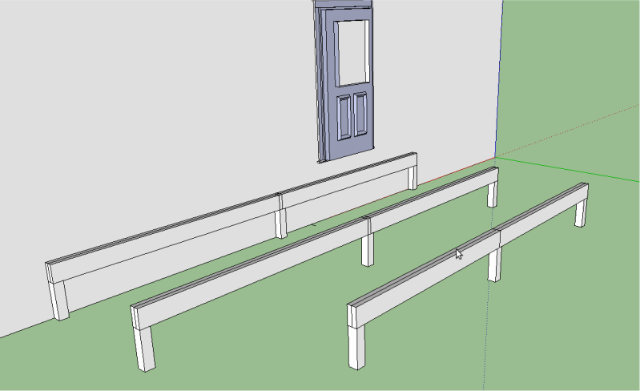

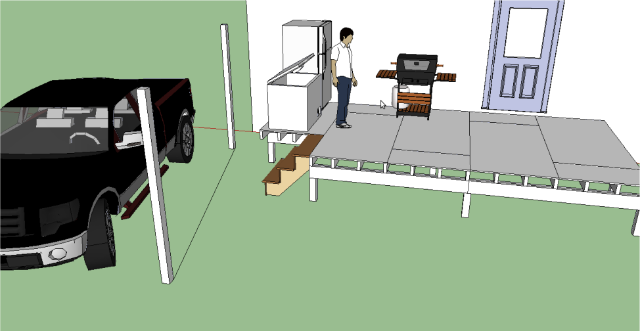

View from the other angle. I didn't put much detail in the house. Just the one wall, and only part of it. The house continues on to the right much further than I drew.

Yes, one of the rows is shorter than the other two. This will be explained.

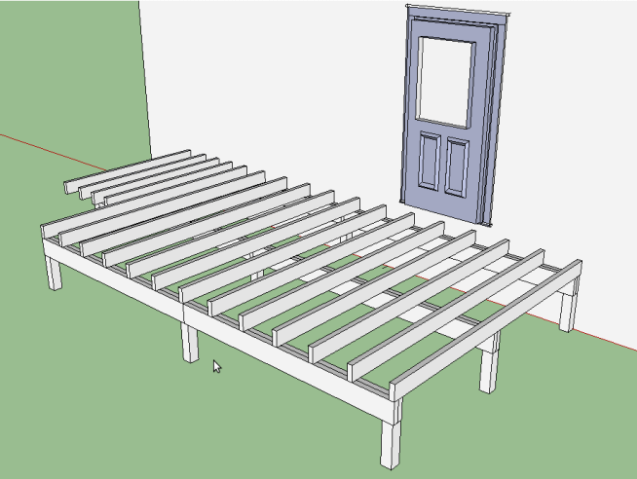

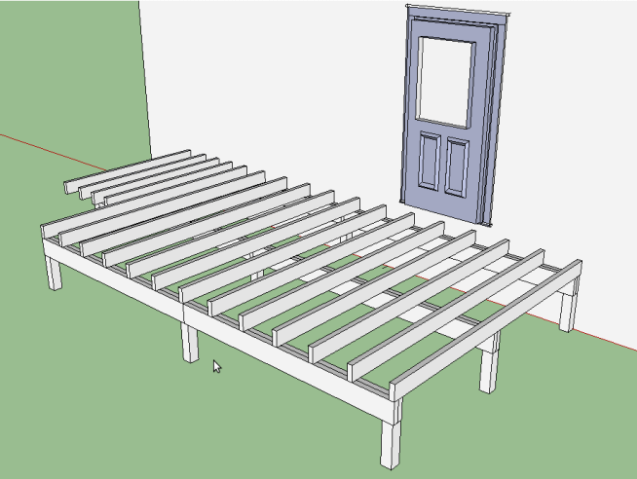

On top of the beams is the floor joists. Notice the "extension" on the far end. This will be a "nook" of sorts for the fridge and freezer.

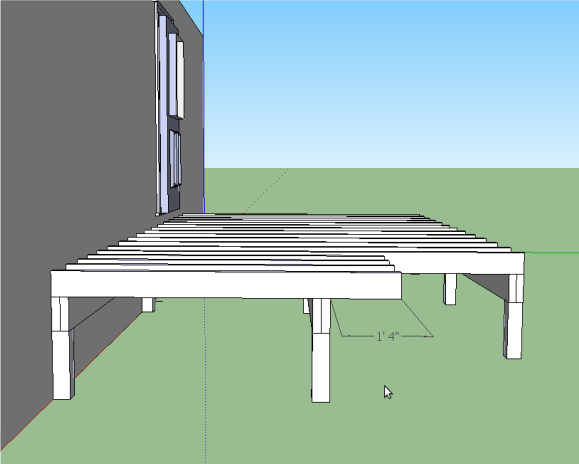

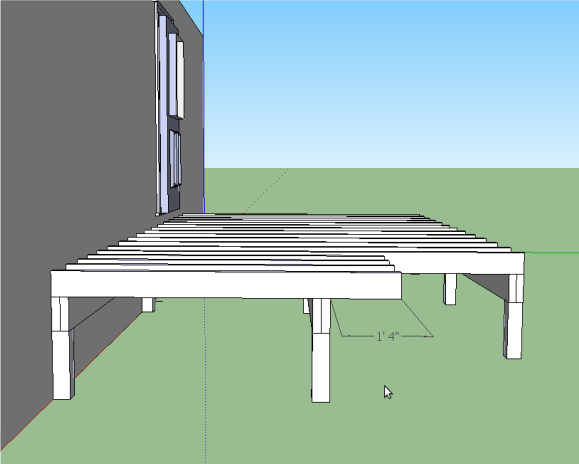

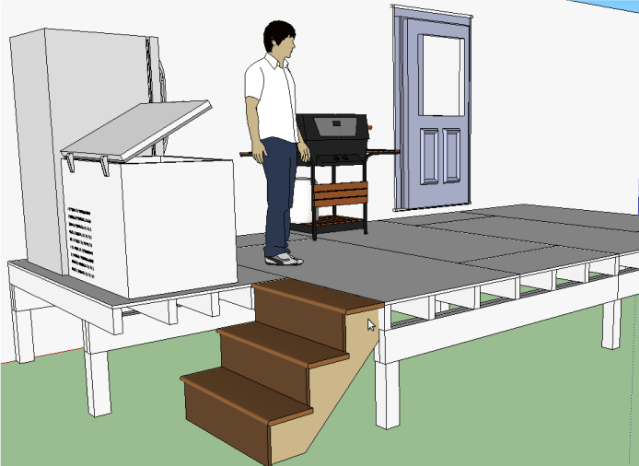

View from the other end. This illustrates one of the big questions I had with this design. Is that 1' 4" overhang acceptable? This would place the beam almost directly under the center of the freezer.

My wife is pretty set on having a screened in back porch. Some place we can grill and hang out and be "outside" but not be eaten up with these giant mosquitoes that Texas keeps sending over to invade us. There's an existing vehicle covering right off from the porch that we built when we originally lived there. I hope to be able to build a walkway covering between the two. It's a pretty short span, so that shouldn't be a problem. The porch will be off the back left corner of the house.

Here's what I've come up with in Sketchup. I'm trying to keep it simple and cost efficient, but functional.

Starting out with the 4x4 posts and support beams. The beams are 2"x8" and doubled. Is this necessary for the center span? Should I put a support brace tying the beam together for stability? I took a guess at the height of the posts, but that should be pretty close.

View from the other angle. I didn't put much detail in the house. Just the one wall, and only part of it. The house continues on to the right much further than I drew.

Yes, one of the rows is shorter than the other two. This will be explained.

On top of the beams is the floor joists. Notice the "extension" on the far end. This will be a "nook" of sorts for the fridge and freezer.

View from the other end. This illustrates one of the big questions I had with this design. Is that 1' 4" overhang acceptable? This would place the beam almost directly under the center of the freezer.

Heath

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

On top of the floor joists is 3/4" tongue & groove plywood. And a set of stairs in the indention area.

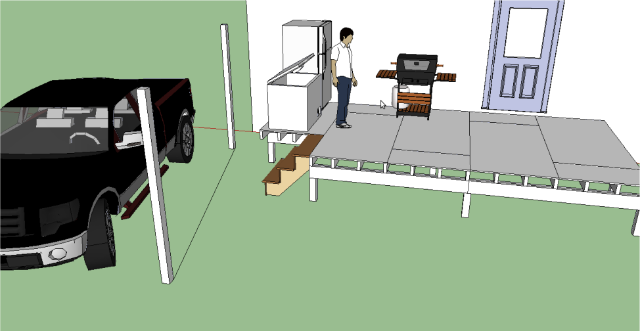

Since the carport sits at angle with the house, the indention (where the stairs are) gives a little elbow room between the porch and carport & truck. The fridge/freezer "nook" makes use of space in the "corner" formed by the house and carport.

I started building the walls in Sketchup, but that was getting tedious and I was getting tired and stayed up way too late last night working on this and I don't have as many questions about the walls as I do the main support structure.

Since the carport sits at angle with the house, the indention (where the stairs are) gives a little elbow room between the porch and carport & truck. The fridge/freezer "nook" makes use of space in the "corner" formed by the house and carport.

I started building the walls in Sketchup, but that was getting tedious and I was getting tired and stayed up way too late last night working on this and I don't have as many questions about the walls as I do the main support structure.

Heath

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Using plywood for the flooring will allow water to set on it.

SS 500(09/1980), DC3300, jointer, bandsaw, belt sander, Strip Sander, drum sanders,molder, dado, biscuit joiner, universal lathe tool rest, Oneway talon chuck, router bits & chucks and a De Walt 735 planer,a #5,#6, block planes. ALL in a 100 square foot shop.

.

.

Bob

.

.

Bob

It will be walled in with a roof. Any rain that is blown in through the screens should be minimal. Any water sitting on it should be removed rather quickly. The plywood will also most likely be painted with a latex paint.beeg wrote:Using plywood for the flooring will allow water to set on it.

I decided on plywood instead of slatted decking as a means to keep bugs out. What good is screening it in if the mosquitoes can just come up between the slats of the floor?

Heath

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

- Ed in Tampa

- Platinum Member

- Posts: 5832

- Joined: Fri Jul 21, 2006 12:45 am

- Location: North Tampa Bay area Florida

heathicus

Yup that will do it but if you used 2x12 instead of 2x6 you could span the 10 ft length without the cost and work of the middle support. Look at any house most floor joist span more than 10 feet but are bigger than 2x6.

Price it both ways using the 2x6 with middle support and 2x12 without and see which is cheaper.

Yup that will do it but if you used 2x12 instead of 2x6 you could span the 10 ft length without the cost and work of the middle support. Look at any house most floor joist span more than 10 feet but are bigger than 2x6.

Price it both ways using the 2x6 with middle support and 2x12 without and see which is cheaper.

Ed in Tampa

Stay out of trouble!

Stay out of trouble!

Thanks, Ed. I will definitely price it out both ways.

Heath

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

Central Louisiana

-10ER - SN 13927, Born 1949, Acquired October 2008, Restored November, 2008

-10ER - SN 35630, Born 1950, Acquired April 2009, Restored May 2009, A34 Jigsaw

-Mark V - SN 212052, Born 1986, Acquired Sept 2009, Restored March 2010, Bandsaw

-10ER - SN 39722, Born 1950, Acquired March 2011, awaiting restoration

-

osx-addict

- Gold Member

- Posts: 386

- Joined: Thu Feb 28, 2008 1:56 pm

- Location: Los Angeles, CA

- JPG

- Platinum Member

- Posts: 34683

- Joined: Wed Dec 10, 2008 7:42 pm

- Location: Lexington, Ky (TAMECAT territory)

1-2x12 costs more than 2-2x6. Assuming you would still double the 2x12 on the sides, than means 4-2x12 vs 6-2x6>> You could buy more than 8-2x6 for the price of 4-2x6'. However the 2x12 are more than 4x as strong as the 2x6. Thus 1-2x12 is twice as strong as 2-2x6! So- - - using a 1 2x12 on each side costs more, but is twice as strong.

The center support is recommended by me. This reduces the flooring span to 5'. Also being centered under the freezer is ideal. I think you would be more satisfied having the center support. Yes the doubling of the center support would be my recommendation. It makes no sense to make it weaker than the outer ones. The objective is to provide equal strain reduction(flexing) across the surface.

I would provide a plate to secure the support beams to the posts and to tie the joint together.(outer surfaces)

Now considering all that you have added to the mix. I suggest the following!

6x6 posts on plynth with a single notch centered to accept the support beam(s). Or a single notch on one side of the post. 10' between posts along the longer sides/center(as per yer sketch)

2x12 support beam(single) resting on the shoulders cut in the 6x6 posts. two bolts per 2x12 end through the 6x6 above the shoulder.(use washers)

Three beams(Include the center beam).

The cantilevering of the truncated area(overhang) is acceptable considering the closeness of the supporting beam. Box in the ends of the joists to prevent them rotating(like bridging does). Short spacer inside, continuous piece outer.(box sill)

Box in the outer ends of the jousts also. Main thing is to prevent the joists from rotating. Bridging over the center beam(or blocking).

How ya gonna tie the joists to the beams? Consider hanging the joists from the outer beams rather then setting them on top. Leave them on top of the center beam. Attach a 2x6 shoulder to the inside of the 2x12 for the joists to rest upon(5 1/2" from the top). This will eliminate the need to box it in(the 2x12 becomes the outside of the box). Increase the notch in the post to include the shoulder 1x6(it is 1/2" shallower) and cut it on the inner side. That would leave 2 1/2" for super structure attachment etc. on the outside. This would require the center beam be 6" higher than the outer ones.

It is an open porch(screened) and is subject to rain accumulation. Provide a minimal outward slope and weep holes in any sides attached on the outer edge. Make sure any water can totally vacate the weep holes. Yes a screen will be needed to keep those pesky blood thirsty insects out!

Definitely more than enough for ONE post!!!

The center support is recommended by me. This reduces the flooring span to 5'. Also being centered under the freezer is ideal. I think you would be more satisfied having the center support. Yes the doubling of the center support would be my recommendation. It makes no sense to make it weaker than the outer ones. The objective is to provide equal strain reduction(flexing) across the surface.

I would provide a plate to secure the support beams to the posts and to tie the joint together.(outer surfaces)

Now considering all that you have added to the mix. I suggest the following!

6x6 posts on plynth with a single notch centered to accept the support beam(s). Or a single notch on one side of the post. 10' between posts along the longer sides/center(as per yer sketch)

2x12 support beam(single) resting on the shoulders cut in the 6x6 posts. two bolts per 2x12 end through the 6x6 above the shoulder.(use washers)

Three beams(Include the center beam).

The cantilevering of the truncated area(overhang) is acceptable considering the closeness of the supporting beam. Box in the ends of the joists to prevent them rotating(like bridging does). Short spacer inside, continuous piece outer.(box sill)

Box in the outer ends of the jousts also. Main thing is to prevent the joists from rotating. Bridging over the center beam(or blocking).

How ya gonna tie the joists to the beams? Consider hanging the joists from the outer beams rather then setting them on top. Leave them on top of the center beam. Attach a 2x6 shoulder to the inside of the 2x12 for the joists to rest upon(5 1/2" from the top). This will eliminate the need to box it in(the 2x12 becomes the outside of the box). Increase the notch in the post to include the shoulder 1x6(it is 1/2" shallower) and cut it on the inner side. That would leave 2 1/2" for super structure attachment etc. on the outside. This would require the center beam be 6" higher than the outer ones.

It is an open porch(screened) and is subject to rain accumulation. Provide a minimal outward slope and weep holes in any sides attached on the outer edge. Make sure any water can totally vacate the weep holes. Yes a screen will be needed to keep those pesky blood thirsty insects out!

Definitely more than enough for ONE post!!!

╔═══╗

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange

- JPG

- Platinum Member

- Posts: 34683

- Joined: Wed Dec 10, 2008 7:42 pm

- Location: Lexington, Ky (TAMECAT territory)

Methinks the screening will be adequate for that purpose(and the smoke will help drive off the long nosed female insects).osx-addict wrote:Don't forget a ventilation system if you're planning on using a BBQ in there -- otherwise the smoke will get you..

╔═══╗

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange

╟JPG ╢

╚═══╝

Goldie(Bought New SN 377425)/4" jointer/6" beltsander/12" planer/stripsander/bandsaw/powerstation /Scroll saw/Jig saw /Craftsman 10" ras/Craftsman 6" thicknessplaner/ Dayton10"tablesaw(restoredfromneighborstrashpile)/ Mark VII restoration in 'progress'/ 10E[/size](SN E3779) restoration in progress, a 510 on the back burner and a growing pile of items to be eventually returned to useful life. - aka Red Grange