Page 20 of 20

Re: Shopsmith's new website is up....

Posted: Sun Jan 14, 2024 1:15 am

by CreekWood

Sorry--I'm going to perpetuate the side branch in this topic by one more comment about quill deflection. I may have been the newbie who got overly fixated on measuring runout after replacing my quill. My method of testing came about while setting up for horizontal boring. I inadvertently bumped the drill bit with my hand while raising the table, and noticing the easy deflection I set up a dial gauge to measure it. Seems like it was 13 thousandths until I locked the quill....but who's going to do that while boring, right? I compromised by tightening the quill lock just shy of Locked.

Re: Shopsmith's new website is up....

Posted: Sun Jan 14, 2024 9:35 am

by JPG

OK so 0.013 in sloppiness in the quill when extended.

Is that actually excessive considering it's intended use is as a wood working machine?

Yes I would prefer it being much less, but . . . .

Re: Shopsmith's new website is up....

Posted: Sun Jan 14, 2024 11:46 pm

by CreekWood

Yes, but that was at the quill. Mount up a chuck, toss in a long drill bit, and it begins to be challenging to hit the mark, say if you're lining up dowel holes. I learned to moderately tighten the quill lock--not so much as to prevent advancing the quill, but "almost tight."

Re: Shopsmith's new website is up....

Posted: Mon Jan 15, 2024 10:04 am

by DLB

I'll try to measure this for comparative purposes, though it's pretty cold in the shop today by local standards so it might be a couple of days. In the interest of producing comparable values: Where are you measuring and where are you applying force? Quill advanced how far, if any? Confirm you are measuring vertical play with the machine in horizontal position. At the "almost tight" setting you use, will the quill retract on its own via the return spring? Where is your dial indicator or equivalent mounted?

The SS quill outer barrel (steel) advances in two headstock 'bores' (aluminum). The outer bore is a full circle, but the inner bore is in the form of a "C" with the opening facing down when the headstock is horizontal. The lock locks the advance mechanism but also squeezes that "C" inner bore around the quill barrel, so the only time it is actually round and of proper diameter is when it is tightly locked. I'd expect some machine to machine variation with that design. It all works best if the quill barrel and bore are clean and waxed and the lock is only loosened enough to allow it to retract under force of the return spring. The inner bore is difficult to wax, so this may be a candidate for powdered graphite or other dry lube. Because of this design, I anticipate a bit of freeplay when fully unlocked and feel the best we can do is to minimize it as you are doing.

- David

Re: Shopsmith's new website is up....

Posted: Wed Jan 17, 2024 1:42 am

by CreekWood

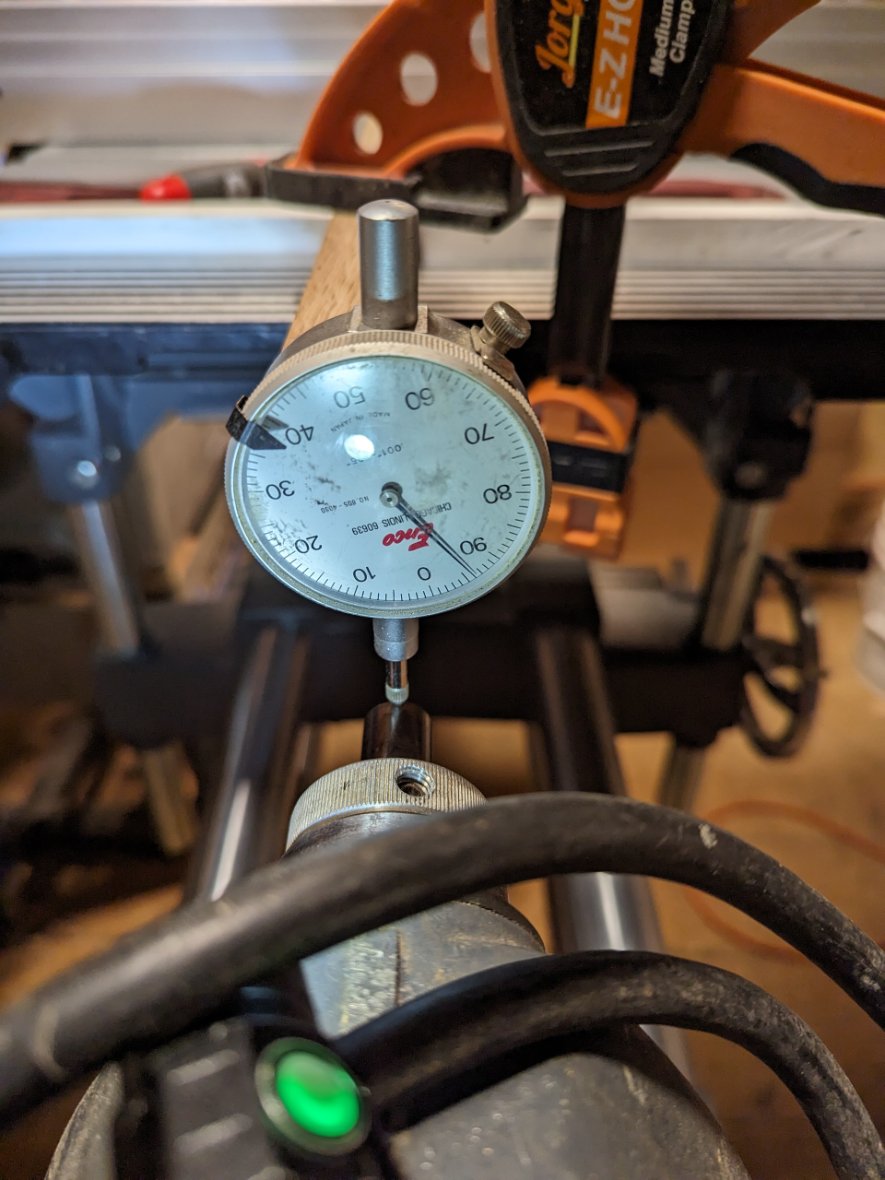

David, I had to go look at my old "Quill Questions" post [not sure how to link back to that] where I said, ".012" play when unlocked" ...not 13. Sorry for the wild exaggeration

. But it did greatly improve by tightening the quill lock, then backing off just a little. The challenges are 1) getting it just barely loose enough for the spring to retract the quill, and 2) how tight/loose that is varies through the quill travel. As to method of measuring, I clamped a dial indicator onto the main table. Table deflection should be even theoretically next to nothing as long as I keep my hands off. I would have to rearrange the dial position to match whatever quill advance I make... Probably makes more sense in the photo I took of how I measured the runout on my original quill, except in this case I pushed the quill up, then down to induce the deflection:

- Measuring Quill Runout

- PXL_20230718_015655349.jpg (136.35 KiB) Viewed 186122 times

Re: Shopsmith's new website is up....

Posted: Wed Jan 17, 2024 10:50 am

by DLB

I copied the above post into a new thread entitled Quill Freeplay under Maintenance.

- David

Re: Shopsmith's new website is up....

Posted: Fri Jan 19, 2024 1:32 pm

by chapmanruss

Back to the new website.

This morning, I noticed doing a search that old part numbers that have been changed no longer automatically update to the new number. I was checking the price of a Belt Sander Eccentric Mounting Post and using the old 6-digit number (513777) it came up as not found. In this case I had to add the 9 at the end of the number (5137779) for the current part number to be able to find it. This number change adding the 9 to the end of the previous 6-digit part number is common to the SPT Mounting Posts.