Making a Router Table that fits on my 510

Moderators: HopefulSSer, admin

Making a Router Table that fits on my 510

anyone tried making a router table to work on you shopsmith 510 or other shopsmiths. looking for ideas of how to do it

- curiousgeorge

- Platinum Member

- Posts: 880

- Joined: Tue Feb 27, 2007 1:00 am

- Location: Fort Worth, Texas

- dusty

- Platinum Member

- Posts: 21371

- Joined: Wed Nov 22, 2006 6:52 am

- Location: Tucson (Wildcat Country), Arizona

Are you thinking about a router that simply resides on the Mark. If you are thinking of the later, I would give up on that thought immediately due to speed deficiency.THOMRIDER wrote:anyone tried making a router table to work on you shopsmith 510 or other shopsmiths. looking for ideas of how to do it

If you are thinking of mounting a router table (with router) on that Mark V that is doable. I would think along the lines of one of the following:

Pro Fence Router Table System (555865)

http://www.shopsmith.com/ownersite/item ... =Find+Item

OR

Router Table Kit (555658)

http://www.shopsmith.com/ownersite/item ... =Find+Item

Either approach could be built and assembled by anyone but would best be done (most easily be done) after buying some select parts from Shopsmith. Might be more work than worth.

I have both and find them each useful in their own ways. If I had to select one over the other I would chose the 555865.

"Making Sawdust Safely"

Dusty

Sent from my Dell XPS using Firefox.

Dusty

Sent from my Dell XPS using Firefox.

- a1gutterman

- Platinum Member

- Posts: 3653

- Joined: Tue Jan 09, 2007 12:45 am

- Location: "close to" Seattle

Welcome, THOMRIDER,THOMRIDER wrote:anyone tried making a router table to work on you shopsmith 510 or other shopsmiths. looking for ideas of how to do it

If making one yourself, you might have a look at the picture of the one that SS sells. SS also makes a router table that is included with the Incra Ultimate Fence/Router System Packagefor the 510. This table has rails for the 5' tubes and does knot seem to be available separately (item #522155, which does knot come up as a good item number). The member that, today, started another thread, might be interested in talking to you about their table. That member might want to buy a different tablethat will fit their 520 table system. Hope this has helped you.

The item #555865 fits the 520 table system and will knot work on the 510 table system. The 555865 is the table that camilleraven needs, and camilleraven has the table that wood work for you, the 522155.

In order for the 555865 to work for you, you will need to upgrade your table system to 520.

Tim

Buying US made products will help keep YOUR job or retirement funds safer.

Buying US made products will help keep YOUR job or retirement funds safer.

I purchased a Rockler router table top, and added some 510 rails on angle iron underneath to help hold it in place on the shopsmith. Now when I need to use my router table, I set the lefthand extention table to the same height as the main table, place the router table top on the extension table and main table, run the 2' tubes through the rails and tighten them down. Makes a very stable and inexpensive router table for a small shop. When I'm not using the table, I can lean it against the wall where it takes up little space.

Sorry, I have no pictures at the moment, I'll see if I can post them later.

Sorry, I have no pictures at the moment, I'll see if I can post them later.

Doug

Shopsmith Mark V model 500 upgraded to a model 520, bandsaw, Belt Sander, Jointer, Dewalt DW735 planer, Sand Flee

Shopsmith Mark V model 500 upgraded to a model 520, bandsaw, Belt Sander, Jointer, Dewalt DW735 planer, Sand Flee

THAT is exactly what I want to make

man thanks for the link I want to make that exact table, I will have to find some 510 tubing somewhere for cheap if possible so it will work the way I want.

- a1gutterman

- Platinum Member

- Posts: 3653

- Joined: Tue Jan 09, 2007 12:45 am

- Location: "close to" Seattle

FYI, the router table that I received from ShopSmith with my Incra Ultimate package (for model 510 table system), is exactly like that, except the placement of the router plate is in the center of the table.THOMRIDER wrote:man thanks for the link I want to make that exact table, I will have to find some 510 tubing somewhere for cheap if possible so it will work the way I want.

Tim

Buying US made products will help keep YOUR job or retirement funds safer.

Buying US made products will help keep YOUR job or retirement funds safer.

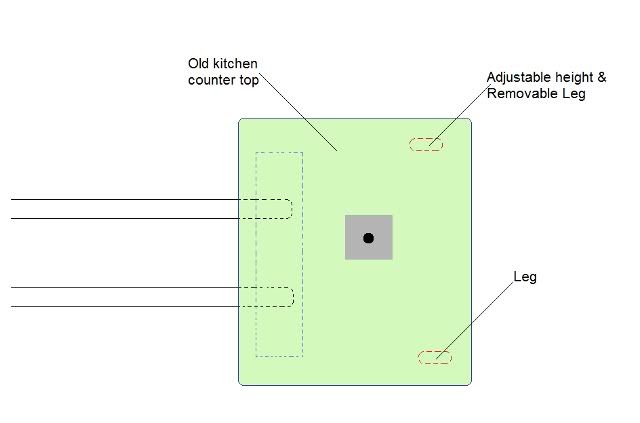

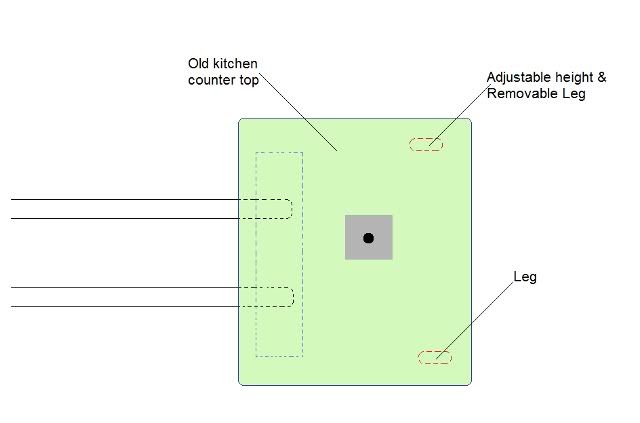

Hi Thomrider. Thanks for starting this thread. It got me thinking about how I could make router table that attaches to my older (500) Shopsmith.

I had a senior moment and posted my original idea in the thread John started showing his router table.

This was my original idea:

I have some old counter top with 3/4" plywood that I will probably use. After clamping the counter top to the the extension table, I don't think legs are necessary. I do have a shaper fence. Can I use that?

The only router I have is a Sear's Craftsman, about 30 years old. It does have a removable baseplate.

Here is what it looks like from underneath:

I'm going to check out some stores this afternoon, and maybe I will find the answers to my questions.

I need a different baseplate. What do you use for that?

Do you just cut a hole in the top that is large enough for the router to pass through and then do some careful routing about an 1/8" deep to hold the router's baseplate that extends out from the router?

If any of you have any tips on this, I'd appreciate your input.

Thanks,

Jerry Floren

St. Peter, MN

I had a senior moment and posted my original idea in the thread John started showing his router table.

This was my original idea:

I have some old counter top with 3/4" plywood that I will probably use. After clamping the counter top to the the extension table, I don't think legs are necessary. I do have a shaper fence. Can I use that?

The only router I have is a Sear's Craftsman, about 30 years old. It does have a removable baseplate.

Here is what it looks like from underneath:

I'm going to check out some stores this afternoon, and maybe I will find the answers to my questions.

I need a different baseplate. What do you use for that?

Do you just cut a hole in the top that is large enough for the router to pass through and then do some careful routing about an 1/8" deep to hold the router's baseplate that extends out from the router?

If any of you have any tips on this, I'd appreciate your input.

Thanks,

Jerry Floren

St. Peter, MN

- a1gutterman

- Platinum Member

- Posts: 3653

- Joined: Tue Jan 09, 2007 12:45 am

- Location: "close to" Seattle

Hi Jerry,bluekayak wrote:...

I need a different baseplate. What do you use for that?

Do you just cut a hole in the top that is large enough for the router to pass through and then do some careful routing about an 1/8" deep to hold the router's baseplate that extends out from the router?

If any of you have any tips on this, I'd appreciate your input.

Thanks,

Jerry Floren

St. Peter, MN

Here is one idea for your base plate. You can cut the plate down if you want to, and yes, your idea of routing out an edge for the base plate to rest in will work, but you can also buy levelers to adjust the edges of your base plate that work with a through hole rather then a routed edge.

Tim

Buying US made products will help keep YOUR job or retirement funds safer.

Buying US made products will help keep YOUR job or retirement funds safer.